Page last updated 30/08/2018

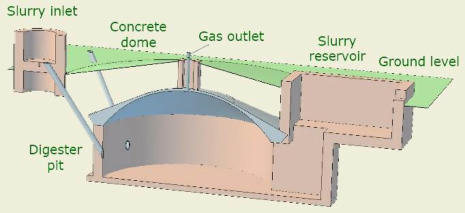

Concrete dome biogas plant (Janata) design

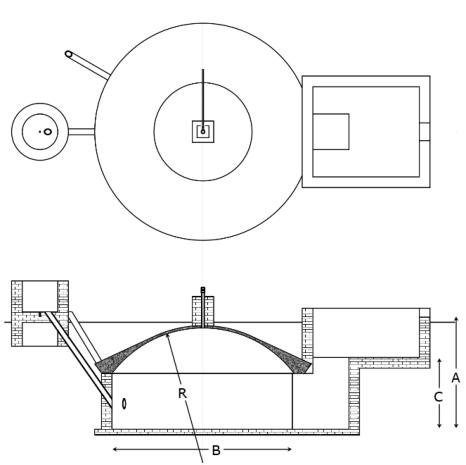

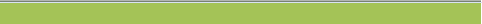

Parameters for concrete dome design

Parameter

Length (m)

A

1.62

B

2.04

C

0.86

R

1.13

Drawing of a concrete dome plant

Diagram of a concrete dome plant used in Nepal

The GGC 2047 biogas plant was first developed by DCS and improved and used by GGC for the extension work under UNDP. A

standardised design was used, to allow for quality control. The plant is built by digging a hole, placing a floor and then building a

cylindrical wall, with one or more slurry feed pipes and a slurry outlet put in place. The hole is refilled with soil and the top is

shaped with a template, that acts as a mould for the concrete dome. Once the concrete has set, the soil is dug out and the inlet

and reservoir tanks built with bricks. The dome is then backfilled with earth to place it under compression.

A standard GGC 2047 plant has a calculated total internal volume of 6 m

3

, although not all of the internal volume is used for slurry.

The design is very strong and a survey of installed plants showed that 95% survived an earthquake in Nepal, although many of the

gas lines broke.

The equations for a volume of a section of a sphere can be used to calculate the volume of the dome while the cylindrical section is

given by the relevant equation.

There are a range of different sizes for GGC 2047 concrete dome plants, including much larger ones.

More details of biogas plant designs are given in the book.

Page last updated 30/08/2018

Diagram of a concrete

dome plant used in Nepal

The GGC 2047 biogas plant was first developed by DCS and

improved and used by GGC for the extension work under

UNDP. A standardised design was used, to allow for quality

control. The plant is built by digging a hole, placing a floor and

then building a cylindrical wall, with one or more slurry feed

pipes and a slurry outlet put in place. The hole is refilled with

soil and the top is shaped with a template, that acts as a

mould for the concrete dome. Once the concrete has set, the

soil is dug out and the inlet and reservoir tanks built with

bricks. The dome is then backfilled with earth to place it under

compression.

A standard GGC 2047 plant has a calculated total internal

volume of 6 m

3

, although not all of the internal volume is used

for slurry. The design is very strong and a survey of installed

plants showed that 95% survived an earthquake in Nepal,

although many of the gas lines broke.

The equations for a volume of a section of a sphere can be

used to calculate the volume of the dome while the cylindrical

section is given by the relevant equation.

Parameters for concrete dome

design

Parameter

Length (m)

A

1.62

B

2.04

C

0.86

R

1.13

Drawing of a concrete

dome plant used in Nepal